Chanter Stop "pin"

- lordofthestrings

- Posts: 583

- Joined: Sun Oct 01, 2006 5:51 pm

- antispam: No

- Please enter the next number in sequence: 8

- Location: Mundelein, IL

Chanter Stop "pin"

Hi all

I threw around a lot of ideas for a DIY chanter stop mechanism. I tried a few of these ideas out, and my lack of specialty tools and know how became an immediate problem.

I did get one to work well, though, and will post a pic soon. Here's what it is:

Its a normal looking brass chanter top, with no obsious difference, except for a pin on the top with a maple bead (not at all unlike a regulator tuning pin). When it is pushed down, (normal position) the chanter is engaged, there is wind flow, and ytou play away. When you pull the bead up about a 1/2 inch, the cnater will shut off. This frees up both hands, and makes tuning drones easy. This is not a "quick stop" thing to shuit off faast while playing, but works very well, and is descrete.

Thoughts?

I threw around a lot of ideas for a DIY chanter stop mechanism. I tried a few of these ideas out, and my lack of specialty tools and know how became an immediate problem.

I did get one to work well, though, and will post a pic soon. Here's what it is:

Its a normal looking brass chanter top, with no obsious difference, except for a pin on the top with a maple bead (not at all unlike a regulator tuning pin). When it is pushed down, (normal position) the chanter is engaged, there is wind flow, and ytou play away. When you pull the bead up about a 1/2 inch, the cnater will shut off. This frees up both hands, and makes tuning drones easy. This is not a "quick stop" thing to shuit off faast while playing, but works very well, and is descrete.

Thoughts?

- - - Spence - - -

A little autobiography, including pictures, Here

Actually, I hate music. I'm only doing this for the money.

A little autobiography, including pictures, Here

Actually, I hate music. I'm only doing this for the money.

- lordofthestrings

- Posts: 583

- Joined: Sun Oct 01, 2006 5:51 pm

- antispam: No

- Please enter the next number in sequence: 8

- Location: Mundelein, IL

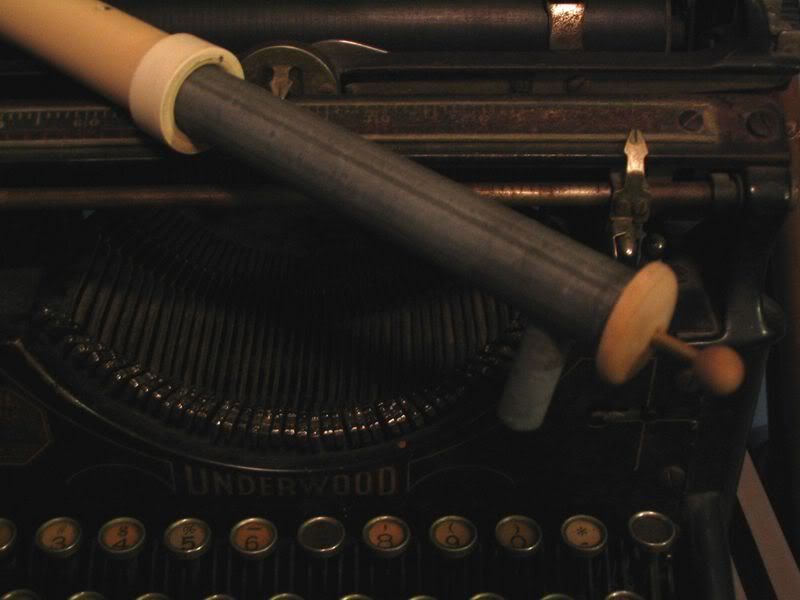

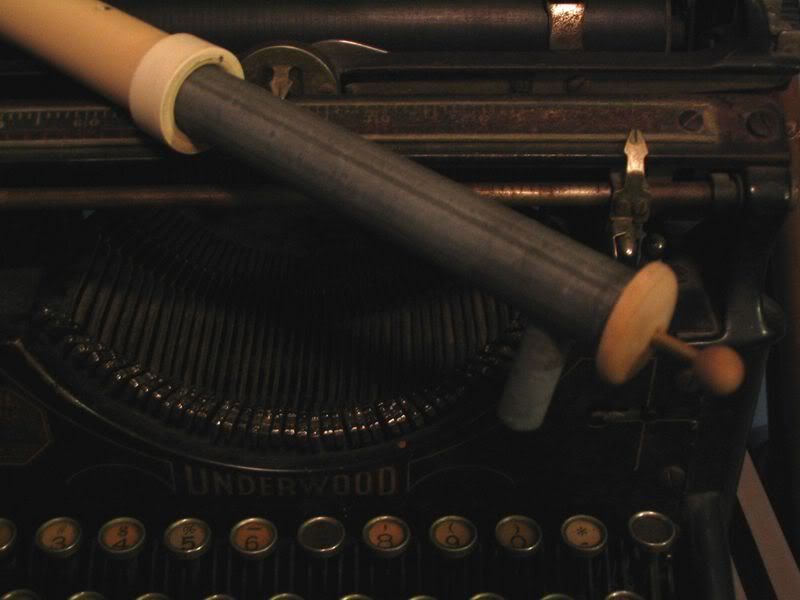

Here are the pictures:

With the bead "in" (pushed down), windway open

With the bead "out" (pulled up), windway closed

Sorry, I lied, this one is an aluminum top. This is a very discreet was to have a chanter stop, looks sorta cool, and is very reliable. I tend to engage it using my chin to puch in if i need to start playing fast (which I rarely do). Not the best boon for needing to start/stop quick, but if ya like a little to have drones going while playing something else, or want to do a little "reg-ing" this works pretty well.

Now I just gotta sell the idea to someone and become a bajillionaire. Any takers?

Any takers?

And sorry for all the spelling and etc. errors in the prior post, was dodging fireballs and trying to save the princess from the evil Bowser.

[/list]

With the bead "in" (pushed down), windway open

With the bead "out" (pulled up), windway closed

Sorry, I lied, this one is an aluminum top. This is a very discreet was to have a chanter stop, looks sorta cool, and is very reliable. I tend to engage it using my chin to puch in if i need to start playing fast (which I rarely do). Not the best boon for needing to start/stop quick, but if ya like a little to have drones going while playing something else, or want to do a little "reg-ing" this works pretty well.

Now I just gotta sell the idea to someone and become a bajillionaire.

And sorry for all the spelling and etc. errors in the prior post, was dodging fireballs and trying to save the princess from the evil Bowser.

[/list]

- - - Spence - - -

A little autobiography, including pictures, Here

Actually, I hate music. I'm only doing this for the money.

A little autobiography, including pictures, Here

Actually, I hate music. I'm only doing this for the money.

Sorry but this would be unpatentable as there is nothing new or innovative here as virtually every NSP has the same stop mechanism on its drones.

My own maker experimented with a similar idea around 5 to 6 years ago with the plunger operated by a push/pull rod that came down the side of the chanter top piece to bring it in line with the back 'd' thumb. He didn't like the ascetics of it and has stayed with the rear fitted conventional stop key like the Taylor's

John

My own maker experimented with a similar idea around 5 to 6 years ago with the plunger operated by a push/pull rod that came down the side of the chanter top piece to bring it in line with the back 'd' thumb. He didn't like the ascetics of it and has stayed with the rear fitted conventional stop key like the Taylor's

John

- PJ

- Posts: 5889

- Joined: Tue Jan 18, 2005 12:23 pm

- antispam: No

- Please enter the next number in sequence: 8

- Tell us something.: ......................................................................................................

- Location: Baychimo

Apart from that, a patent costs approx. $25,000 to obtain. You'd want to sell a lot of valved chanter tops to make the venture profitable!!Elmek wrote:Sorry but this would be unpatentable as there is nothing new or innovative here as virtually every NSP has the same stop mechanism on its drones.

PJ

- vanfleet

- Posts: 204

- Joined: Wed Jul 09, 2003 2:43 pm

- antispam: No

- Please enter the next number in sequence: 8

- Tell us something.: I play a full set of Seth Gallagher uilleann pipes, have been taking lessons, listening, and practicing since 1983. Teachers have included Bill Ochs, and David Power.

- Location: Mifflinburg, PA

chanter stop

Lordofthestrings wrote:

Seriously, though, don't you think a stop mechanism needs to be within reach while you have your fingers covering the chanter holes, such as a stop key or a twist style closure? Ideally, I would like it to be subtle enough to escape the notice of the audience.

JVF

I don't have a chanter stop valve on my set, so I just bite the bag neck to get the same effect . . .I tend to engage it using my chin to push in if i need to start playing fast

Seriously, though, don't you think a stop mechanism needs to be within reach while you have your fingers covering the chanter holes, such as a stop key or a twist style closure? Ideally, I would like it to be subtle enough to escape the notice of the audience.

JVF

My own maker puts the stop key on the back and would you believe he had a customer a while back come complaining that this was wrong. Why did he say this - because an inexperienced maker told him it was a mistake and it should always be on the front.a stop mechanism needs to be within reach while you have your fingers covering the chanter holes, such as a stop key or a twist style closure? Ideally, I would like it to be subtle enough to escape the notice of the audience

Historically the Taylors and those that followed them did but are there any other modern makers that do this.

John

- Brian Lee

- Posts: 3059

- Joined: Tue Jun 26, 2001 6:00 pm

- antispam: No

- Please enter the next number in sequence: 8

- Location: Behind the Zion Curtain

- Contact:

Or you could make the top plug of the windcap long enough to extend down past the inlet tube. Then drill a hole in the side of the plug that matched the inlet, and another up from the bottom of the plug to meet the side opening. All you have to do then is a quick quarter twist of the top cap to shut off or open up the airflow. Simple.

- Joseph E. Smith

- Posts: 13780

- Joined: Sat Mar 06, 2004 2:40 pm

- antispam: No

- Location: ... who cares?...

- Contact:

- simonknight

- Posts: 375

- Joined: Thu Sep 29, 2005 7:53 am

- Please enter the next number in sequence: 1

- Location: Southeastern PA USA

That's exactly how the cap on my Gallagher chanter works. It works quite well, but you have to be precise getting the marks to line up. I have a top with a stop key on order.Brian Lee wrote:Or you could make the top plug of the windcap long enough to extend down past the inlet tube. Then drill a hole in the side of the plug that matched the inlet, and another up from the bottom of the plug to meet the side opening. All you have to do then is a quick quarter twist of the top cap to shut off or open up the airflow. Simple.

Simon

- billh

- Posts: 2159

- Joined: Mon Jan 05, 2004 6:15 am

- Please enter the next number in sequence: 1

- Location: Skerries, County Dublin

- Contact:

I do it either way depending on the customer. I prefer having the stop key on the back, unless the customer is heavy on the thumb-brushed d triplets.Elmek wrote:My own maker puts the stop key on the back and would you believe he had a customer a while back come complaining that this was wrong. Why did he say this - because an inexperienced maker told him it was a mistake and it should always be on the front.a stop mechanism needs to be within reach while you have your fingers covering the chanter holes, such as a stop key or a twist style closure? Ideally, I would like it to be subtle enough to escape the notice of the audience

Historically the Taylors and those that followed them did but are there any other modern makers that do this.

John

This seems to be the way Egan and Coyne did it.

Bill

- reedbiter

- Posts: 285

- Joined: Sat Mar 04, 2006 8:45 pm

- Please enter the next number in sequence: 1

- Location: Roseville, Minnesota

- Contact:

workable//

Yep...for some reason I decided I needed to create something over-engineered and complex..just for the heck of it! Heh...yep, I did a "spring loaded" mechanism...essentially like a Bic Pen. You click the button and it shut off the air supply, click the button again and the air supply was back on....

I've been told that I'd re-invent the stick if I had the time...

I've been told that I'd re-invent the stick if I had the time...

- MarkS

- Posts: 242

- Joined: Sat May 22, 2004 3:03 pm

- Please enter the next number in sequence: 1

- Location: Southeastern PA, USA

Re: workable//

Well, hey, a chanter after all is really nothing more than a needlessly complicated stick...reedbiter wrote:I've been told that I'd re-invent the stick if I had the time...

Cheers,

Mark

"There's never enough time to do all the nothing you want."

Bill Watterson, Calvin and Hobbes

Mark

"There's never enough time to do all the nothing you want."

Bill Watterson, Calvin and Hobbes

- maw

- Posts: 354

- Joined: Fri Apr 23, 2004 8:51 am

- Please enter the next number in sequence: 1

- Location: New Mills in Derbyshire, UK

Elmek wrote:My own maker puts the stop key on the back and would you believe he had a customer a while back come complaining that this was wrong. Why did he say this - because an inexperienced maker told him it was a mistake and it should always be on the front.a stop mechanism needs to be within reach while you have your fingers covering the chanter holes, such as a stop key or a twist style closure? Ideally, I would like it to be subtle enough to escape the notice of the audience

Historically the Taylors and those that followed them did but are there any other modern makers that do this.

John

Obviously your pipemaker was so experienced, his machinery outdates any form of Health & Safety legislation... Hmmm....Elmek wrote:Bay

Where are you. Location might help as there are pipers all over the world and not all annouce their presense

Apprenticeship - depends on the maker as some do and some do not.

Taking on an apprentice can be problematical for some. I was able to watch a lot of my set being made as I lived only 1/2 mile from my maker but he could not take me on as most of the machinery in his workshop was not in line with current UK standards.

John

The Mechanoids will obey the DALEKS... or be exterminated!!!