Different Delrin Feels

- Jayhawk

- Posts: 3900

- Joined: Tue Oct 15, 2002 6:00 pm

- antispam: No

- Please enter the next number in sequence: 8

- Tell us something.: Well, just trying to update my avatar after a decade. Hope this counts! Ok, so apparently I must babble on longer.

- Location: Lawrence, KS

- Contact:

Re: Different Delrin Feels

I played an ebonite flute for close to 4 years and played it outside frequently, and it did not discolor. I think modern ebonite has less of a problem with UV discoloration.

-

flyingparchment

- Posts: 44

- Joined: Sun May 12, 2019 4:02 pm

- antispam: No

- Please enter the next number in sequence: 8

- Tell us something.: i have an unhealthy obsession with flutes and thought i should try to find some other people to share my problems with! (i play a TJ Boehm-system flute and an M&E 6-key simple system flute i've just acquired, hence the interest in C&F.)

Re: Different Delrin Feels

are you sure it's Delrin? i know they advertise one of their flutes as Delrin(TM), but it's absolutely identical to the M&E polymer flute, which is not Delrin. someone else recently mentioned that McNeela is claiming to sell Cocuswood flutes for a price at which it clearly can't be Cocuswood, so i'm not sure how much i'd trust their claims of the materials used.Andro wrote:I have a McNeela Delrin 6 key flute.

- Conical bore

- Posts: 507

- Joined: Sat Aug 04, 2012 7:12 pm

- antispam: No

- Please enter the next number in sequence: 8

- Location: Pacific Northwest USA

Re: Different Delrin Feels

Forbes and Yola Christie of Windward Flutes have been offering the option of "Torrified" (heat treated) Canadian birds-eye and fiddle-back Maple in addition to tropical hardwoods for their flutes. It's an interesting alternative to using petroleum products to stabilize a softer wood species. It looks very nice, a darker brown than untreated maple. They say it smells like pancakes.PB+J wrote:I have an Ellis flute made of walnut, lined with Marine epoxy that’s awesome, and it makes me wonder again why maple or other more common temperate climate woods can’t be used.

-

cac

- Posts: 121

- Joined: Sat Jun 18, 2016 6:47 pm

- antispam: No

- Please enter the next number in sequence: 8

- Tell us something.: Simple system wooden flutes, keyed and keyless. xxxxxx xxxxxx xxxxxx xxxxxx xxxxxx xxxxxx xxxxxx xxxxxx

- Location: Ontario, Canada

Re: Different Delrin Feels

I have a delrin flute made by Rob Forbes, and I've played delrin flutes made by Dave Copley belonging to others, and none of these are in any way slippery. They have a matt finish but it is very smooth. The material just doesn't seem to be slippery. Are you sure your flute is made of delrin?

-

PB+J

- Posts: 1307

- Joined: Sun Mar 25, 2018 5:40 am

- antispam: No

- Please enter the next number in sequence: 8

- Tell us something.: I'm a historian and the author of "The Beat Cop:Chicago's Chief O'Neill and the Creation of Irish Music," published by the University of Chicago in 2022. I live in Arlington VA and play the flute sincerely but not well

Re: Different Delrin Feels

Conical bore wrote:Forbes and Yola Christie of Windward Flutes have been offering the option of "Torrified" (heat treated) Canadian birds-eye and fiddle-back Maple in addition to tropical hardwoods for their flutes. It's an interesting alternative to using petroleum products to stabilize a softer wood species. It looks very nice, a darker brown than untreated maple. They say it smells like pancakes.PB+J wrote:I have an Ellis flute made of walnut, lined with Marine epoxy that’s awesome, and it makes me wonder again why maple or other more common temperate climate woods can’t be used.

Yes I saw that on their website. I've made a couple guitar necks with "roasted maple" and to me it smells like burned wood. But there may be a difference between "Torrefied" and "roasted" wood. The words get thrown around kind of casually. Pretty sure "torrefication" takes place in a vacuum, but I think roasting can take place in your oven

-

Gcobean

- Posts: 35

- Joined: Sat Feb 02, 2019 6:05 pm

- antispam: No

- Please enter the next number in sequence: 8

- Tell us something.: Paddy Maloney rules! Ok, seriously though, I love the Chieftains. I'm here for whistle and flute discussions. Looking at the classifieds as well.

Re: Different Delrin Feels

Thanks all for the replies.

Re: Different Delrin Feels

And when all else fails there's always Gorilla Snot!

https://www.musiciansfriend.com/accesso ... TCEALw_wcB

https://www.musiciansfriend.com/accesso ... TCEALw_wcB

- Geoffrey Ellis

- Posts: 585

- Joined: Thu Sep 13, 2012 1:15 pm

- antispam: No

- Please enter the next number in sequence: 8

- Tell us something.: Crafting fine quality folk flutes from around the world since 1997, my goal is to create beautiful instruments that have the best possible voice, tuning and response by mixing modern methods with traditional designs.

- Contact:

Re: Different Delrin Feels

I use roasted maple as well, and it does have the advantage of not requiring stabilization (ala something like vacuum resin infusion). It doesn't seem very mobile once it is shaped, since it is pretty well pre-shrunk in the roasting process. However, roasting it does not seem to improve the machining quality of the bore in the same way as resin infusion, and maple can be quite porous (leaking air). When you ream maple, it does not ream anything as smoothly as more conventional flute timbers (blackwood, mopane, boxwood, rosewoods of other types, etc.) I don't oil my bores, so I'm not sure how well it seals the different porous woods. I presume the answer is "quite well" because otherwise Forbes and Yola wouldn't be using it. They are not going to make a flute that leaksConical bore wrote:Forbes and Yola Christie of Windward Flutes have been offering the option of "Torrified" (heat treated) Canadian birds-eye and fiddle-back Maple in addition to tropical hardwoods for their flutes. It's an interesting alternative to using petroleum products to stabilize a softer wood species. It looks very nice, a darker brown than untreated maple. They say it smells like pancakes.PB+J wrote:I have an Ellis flute made of walnut, lined with Marine epoxy that’s awesome, and it makes me wonder again why maple or other more common temperate climate woods can’t be used.

I opt for a coat of clear marine epoxy in the bores of maple instruments, simply because it seals them completely, provides a smoother inner bore surface (improved response) and waterproofs them. There may be hidden disadvantages to this approach, such as finding that fifty years down the road the coat of epoxy flakes off or something like that. I don't think the epoxy manufacturer would own that possibility, and it may be a complete non-issue for the next two centuries. But oil has the advantage of being easily refreshed and maintained by the player. I have oiled some bore in the past and while it is great for closed-grain, dense woods like blackwood or oily tropical woods, it does not (to my ear) work nearly as well on more open-grained woods of less density such as walnut, maple, etc.. They do amazingly well with a hard bore finish.

And of course I also have done vacuum resin stabilizing on such woods. In terms of environmental impact, I'm not sure how "bad" the resin is, either at the manufacturing end, or on the by-product end (during production). Certainly some resin-infused sawdust is going back into the environment. It is the same ongoing discussion we've had here before about how enviro-friendly flute making can realistically be, and is there any such thing as zero-impact? (SPOILER ALERT: there isn't!).

But I love the possibilities offered by roasted maple, simply because it gives a really viable domestic wood option for those who want it. And it can be done at home in your oven. I've been schooled by a guy who roasts maple commercially, and he taught me the basics--it's quite straightforward.

- Geoffrey Ellis

- Posts: 585

- Joined: Thu Sep 13, 2012 1:15 pm

- antispam: No

- Please enter the next number in sequence: 8

- Tell us something.: Crafting fine quality folk flutes from around the world since 1997, my goal is to create beautiful instruments that have the best possible voice, tuning and response by mixing modern methods with traditional designs.

- Contact:

Re: Different Delrin Feels

I suspect the terms are synonymous. One is the "industry" word and the other the DIY term most likely. Cooked maple.PB+J wrote:Conical bore wrote:Forbes and Yola Christie of Windward Flutes have been offering the option of "Torrified" (heat treated) Canadian birds-eye and fiddle-back Maple in addition to tropical hardwoods for their flutes. It's an interesting alternative to using petroleum products to stabilize a softer wood species. It looks very nice, a darker brown than untreated maple. They say it smells like pancakes.PB+J wrote:I have an Ellis flute made of walnut, lined with Marine epoxy that’s awesome, and it makes me wonder again why maple or other more common temperate climate woods can’t be used.

Yes I saw that on their website. I've made a couple guitar necks with "roasted maple" and to me it smells like burned wood. But there may be a difference between "Torrefied" and "roasted" wood. The words get thrown around kind of casually. Pretty sure "torrefication" takes place in a vacuum, but I think roasting can take place in your oven

-

shmuelyosef

- Posts: 7

- Joined: Sat Jun 18, 2011 10:53 am

- antispam: No

- Please enter the next number in sequence: 12

Re: Different Delrin Feels

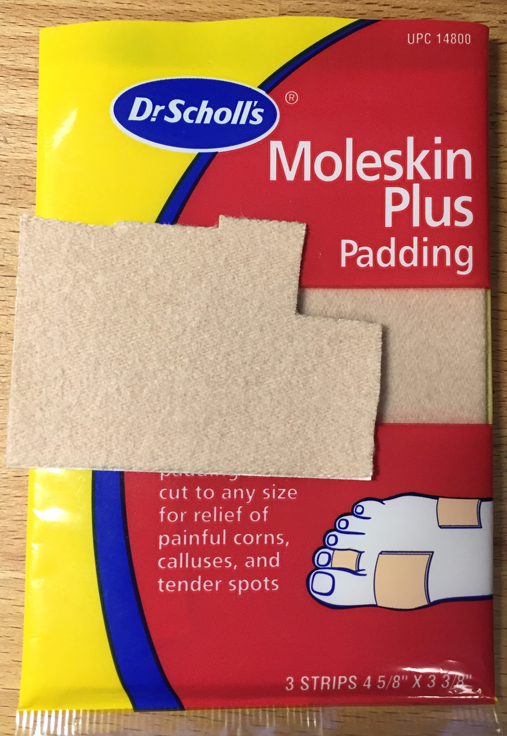

I had this problem on my Alto Boehm flute (silver, not wood or plastic), and the moleskin worked a treat! I can play longer without a blister and it doesn't slide around when my hands get damp...jim stone wrote:One may be able to solve the problem this way. Paste rectangles of moleskin on the delrin flute.

They stick quite nicely. Put one where the flute rests on the left hand, one where my rt pinky rests on the flute, and one where the rt thumb goes. Then, roughen the moleskin by putting superglue or some other glue on the moleskin (the outside of it), so that there is a firm grip. I do this with all my flutes, wooden or delrin. Works well.

- Casey Burns

- Posts: 1488

- Joined: Sun Nov 16, 2003 12:27 pm

- Please enter the next number in sequence: 1

- Location: Kingston WA

- Contact:

Re: Different Delrin Feels

Kinky.

- Steve Bliven

- Posts: 2978

- Joined: Sat Jan 31, 2004 2:06 pm

- antispam: No

- Location: Dartmouth, Massachusetts, USA

Re: Different Delrin Feels

Re: Moleskin

I still get an image of a bunch of bald moles running around — or worse yet, skinless moles ...

Try and un-see that....

Best wishes.

Steve

I still get an image of a bunch of bald moles running around — or worse yet, skinless moles ...

Try and un-see that....

Best wishes.

Steve

Live your life so that, if it was a book, Florida would ban it.

- Jayhawk

- Posts: 3900

- Joined: Tue Oct 15, 2002 6:00 pm

- antispam: No

- Please enter the next number in sequence: 8

- Tell us something.: Well, just trying to update my avatar after a decade. Hope this counts! Ok, so apparently I must babble on longer.

- Location: Lawrence, KS

- Contact:

Re: Different Delrin Feels

Now that's kinky.

-

OOwl

- Posts: 6

- Joined: Tue Feb 07, 2012 3:48 pm

- antispam: No

- Please enter the next number in sequence: 10

Re: Different Delrin Feels

I DO find my Copley delrin to be slippery. Not so with the few wooden flutes I've tried. It is about 9 years old so perhaps he is making them differently now. I placed two pieces of painters (masking) tape where my finger grip and solved the issue. Moleskin is likely more durable but would also be thicker.cac wrote:I have a delrin flute made by Rob Forbes, and I've played delrin flutes made by Dave Copley belonging to others, and none of these are in any way slippery. They have a matt finish but it is very smooth. The material just doesn't seem to be slippery. Are you sure your flute is made of delrin?