Whistle making help needed

Forum rules

Please see forum announcement for description and rules!

Please see forum announcement for description and rules!

-

Tor

- Posts: 399

- Joined: Wed Jun 06, 2012 6:23 am

- antispam: No

- Please enter the next number in sequence: 8

- Location: Europe and Japan

Re: Whistle making help needed

@Tunborough: Thanks for the references!

-Tor

-Tor

- hans

- Posts: 2259

- Joined: Fri Nov 01, 2002 6:00 pm

- antispam: No

- Please enter the next number in sequence: 8

- Tell us something.: I've been making whistles since 2010 in my tiny workshop at my home. I've been playing whistle since teenage times.

- Location: Moray Firth, Scotland

- Contact:

Re: Whistle making help needed

I think 14mm bore can make a successful wider bore high D whistle, it is certainly not too wide. I use it for the wider bore model, and use 13mm bore for the standard whistle.CarvedTones wrote:BTW, I recently made a high D out of what is really too wide a bore (14mm) before I found TWJCalc. TWCalc and flutomat both were off the mark. Comparing to what it actually ended up as when tuned, Hans' tweaked flutomat calculation is much more accurate.

The HB Flutomat Phill incorporated was based on info I gave Phill at the time. It is just a little bit different from the formulas I use now in my calculator.

For end correction instead of 0.56 * whistle bore I use 0.5 * whistle bore, a slightly smaller factor, but still not as small as Kosel's Flutomat end effect factor (which is about 0.3).

I also use a different value for the speed of sound, instead of 345000 mm/sec I use 344543.5 mm/sec (for 25 degrees Centigrade), and use a formula so temperature (of air inside the bore) can be changed.

A public version is on my website here:

http://music.bracker.co/Music/Whistle_Calculator

- CarvedTones

- Posts: 83

- Joined: Tue Mar 23, 2010 5:39 am

- antispam: No

- Location: Raleigh, NC

- Contact:

Re: Whistle making help needed

It certainly can work, but it isn't very forgiving for a beginning whistle maker trying to get a working upper register.hans wrote:I think 14mm bore can make a successful wider bore high D whistle, it is certainly not too wide. I use it for the wider bore model, and use 13mm bore for the standard whistle.

I am making one piece wooden whistles that are historically inspired but with modern tuning right now.

I just ordered another gun drill that is 12.3 mm to try a narrower bore. That's not a magic number, it's just that an eBay seller had some NOS bits that are 0.4840" x 16" at a really good price. The 14mm is exactly what is called for in a plan I have for a historical "recorder" in C. I quoted recorder because purists will argue that it really isn't; it is pretty much a C whistle with some extra holes. But I also have a couple of C whistles and a B flat in the works with the larger bore that I have high hopes for.

-Andy

- Feadoggie

- Posts: 3940

- Joined: Mon Feb 14, 2005 11:06 pm

- antispam: No

- Location: Stout's Valley, PA, USA

Re: Whistle making help needed

Heehee. I bought one of those too. It's not like I needed another gundrill. But you are right, it was a good price. Couldn't pass it up. My drill has not gotten here yet. Have you tried yours out yet, CarvedTones?CarvedTones wrote:That's not a magic number, it's just that an eBay seller had some NOS bits that are 0.4840" x 16" at a really good price.

Feadoggie

I've proven who I am so many times, the magnetic strips worn thin.

- CarvedTones

- Posts: 83

- Joined: Tue Mar 23, 2010 5:39 am

- antispam: No

- Location: Raleigh, NC

- Contact:

Re: Whistle making help needed

No, mine hasn't arrived. I ordered Sunday and got a "it's been mailed" notification on Monday.Feadoggie wrote:Heehee. I bought one of those too. It's not like I needed another gundrill. But you are right, it was a good price. Couldn't pass it up. My drill has not gotten here yet. Have you tried yours out yet, CarvedTones?CarvedTones wrote:That's not a magic number, it's just that an eBay seller had some NOS bits that are 0.4840" x 16" at a really good price.

Feadoggie

EDIT - For the benefit of others:

http://www.ebay.com/itm/ws/eBayISAPI.dl ... 0879631763

It looks like right now, we bought 2 of 9 and the other 7 are still available. They are El Dorado bits (good name brand), dated 10/2008 and a steal at under $25 delivered.

It looks to have a slightly different shank/handle than my current one, so I may have to make another one of my high tech "hikree branch new matic fittins".

-Andy

-

Tunborough

- Posts: 1419

- Joined: Sun Dec 05, 2010 2:59 pm

- antispam: No

- Please enter the next number in sequence: 10

- Location: Southwestern Ontario

Re: Whistle making help needed

I had that coming to me, didn't I?CarvedTones wrote:It might be an interesting option to run it on results of one of the other calculations. The "Tunborough Test" of a generated whistle plan.

Fair enough. Who wants to provide the whistle? I can let you know the measurements I need.

- CarvedTones

- Posts: 83

- Joined: Tue Mar 23, 2010 5:39 am

- antispam: No

- Location: Raleigh, NC

- Contact:

Re: Whistle making help needed

I meant to take the results of one of the other calculations and run them through your calculation and spit out a report (or just simple status) that says it seems to make sense or not. He has 3 (actually appears as 4 choices but I am not sure what "Script" is) different algorithms as choices that generate plans. Your algorithm validates plans instead of producing them if I understood your earlier comment correctly. So offering it as an option to validate makes sense to me.Tunborough wrote:I had that coming to me, didn't I?CarvedTones wrote:It might be an interesting option to run it on results of one of the other calculations. The "Tunborough Test" of a generated whistle plan.

Fair enough. Who wants to provide the whistle? I can let you know the measurements I need.

-Andy

- hans

- Posts: 2259

- Joined: Fri Nov 01, 2002 6:00 pm

- antispam: No

- Please enter the next number in sequence: 8

- Tell us something.: I've been making whistles since 2010 in my tiny workshop at my home. I've been playing whistle since teenage times.

- Location: Moray Firth, Scotland

- Contact:

Re: Whistle making help needed

I don't see how one can validate one mathematical model by another, validation has to come through testing of physical instruments. But it may be interesting to see the differences, and especially cool to use the output of one model as the input of another and then compare theoretical frequency deviations directly (and then you start wondering what part in what model needs modifications).CarvedTones wrote:I meant to take the results of one of the other calculations and run them through your calculation and spit out a report (or just simple status) that says it seems to make sense or not. He has 3 (actually appears as 4 choices but I am not sure what "Script" is) different algorithms as choices that generate plans. Your algorithm validates plans instead of producing them if I understood your earlier comment correctly. So offering it as an option to validate makes sense to me.Tunborough wrote:I had that coming to me, didn't I?CarvedTones wrote:It might be an interesting option to run it on results of one of the other calculations. The "Tunborough Test" of a generated whistle plan.

Fair enough. Who wants to provide the whistle? I can let you know the measurements I need.

I am amazed how useful tone hole calculations can be, and with a bit of tweaking the algorithms they can get even better. Such tweaking may or may not make any theoretical sense, but works in praxis, and that's what counts for me as a whistle maker. If it would also make theoretical sense it would be even better of course!

As to the "Script" option in Phill's Whistle Calculator: it loads the functions of the Kosel Flutomat as default, and using the menu option "Edit Javascript" under "Edit" one can directly edit those functions, or load the functions of the other calculating algorithms provided, and even save changes to functions as a custom "Script" and load a customised script. So it provides advanced ways of tweaking a model.

- CarvedTones

- Posts: 83

- Joined: Tue Mar 23, 2010 5:39 am

- antispam: No

- Location: Raleigh, NC

- Contact:

Re: Whistle making help needed

Validate was probably the wrong word. I was thinking of what Tunborough said about his calculations:hans wrote:I don't see how one can validate one mathematical model by another, validation has to come through testing of physical instruments. But it may be interesting to see the differences, and especially cool to use the output of one model as the input of another and then compare theoretical frequency deviations directly (and then you start wondering what part in what model needs modifications).

It might be nice to be warned that the dimensions I have chosen will likely have one or more notes that are not stable, like it warns about low cutoff ratios. I like TWJCalc a lot; it is perfect for amateur hacks like me. It doesn't inundate me with data, just gives me a single value as an indication of whether or not the hole will work in more than one octave (and lights it up in red to warn me when it won't), has the simple graph to let me see how consistent I have the values (I know that the value of consistency in those values is debatable) and a reasonable approximation of what it will look like so I can see if the spacing is about right for human fingers. Allowing me to enter my drill bit sizes (and leave out the one that has gone missingTunborough wrote:As I recall, TWJCalc and Flutomat provide dimensions for given frequencies. This model, on the other hand, calculates playing frequencies for given dimensions, so going the other way requires an additional layer. And rather than a frequency for each note, it gives a range of frequencies, between where it jumps to the next register up, and where it drops down a register or (in the first register) doesn't play a very stable note.

In some respects, I may be talking in circles here since I say I like the simplicity but maybe the complex test should be added, but it might be nice as an additional step/option after I have made adjustments and think I have a good plan. At some point, you have to make the whistle to find out if it is a good plan. I just want to avoid that on ones that have a deficiency that can be detected by calculations.

That is pretty cool that you can edit the calculations. I am actually a software developer, but when I go home I just want to make whistles not mess with more code. Besides, if I use it as is then when a whistle turns out bad I can blame Kosel, Bingamon or Bracker

-Andy

-

Tunborough

- Posts: 1419

- Joined: Sun Dec 05, 2010 2:59 pm

- antispam: No

- Please enter the next number in sequence: 10

- Location: Southwestern Ontario

Re: Whistle making help needed

That's what I had in mind. While we could compare model to model, we wouldn't know what any discrepancies meant without the real whistle, as Hans has suggested.hans wrote:Validation has to come through testing of physical instruments.

- DrPhill

- Posts: 1610

- Joined: Wed Nov 19, 2008 11:58 am

- antispam: No

- Please enter the next number in sequence: 10

- Location: None

Re: Whistle making help needed

I could certainly add the extra calculation/validation step into TWJCalc if that is what is wanted. I would probably do it as a second tab panel behind the current panel. I would probably separate the tuner functionality from the current panel, and either incorporate it into the new functionality, or make a third panel for it.

It would make quite a nice process:

- Choose your key and scale

- Specify your tube and embouchure

- Play with the hole specifications

- Then switch to the playing frequency analysis

- Then use the tuner when building the whistle.

As Hans knows I am happy to make the software as usable as I can........

It would make quite a nice process:

- Choose your key and scale

- Specify your tube and embouchure

- Play with the hole specifications

- Then switch to the playing frequency analysis

- Then use the tuner when building the whistle.

As Hans knows I am happy to make the software as usable as I can........

- CarvedTones

- Posts: 83

- Joined: Tue Mar 23, 2010 5:39 am

- antispam: No

- Location: Raleigh, NC

- Contact:

Re: Whistle making help needed

DrPhill,

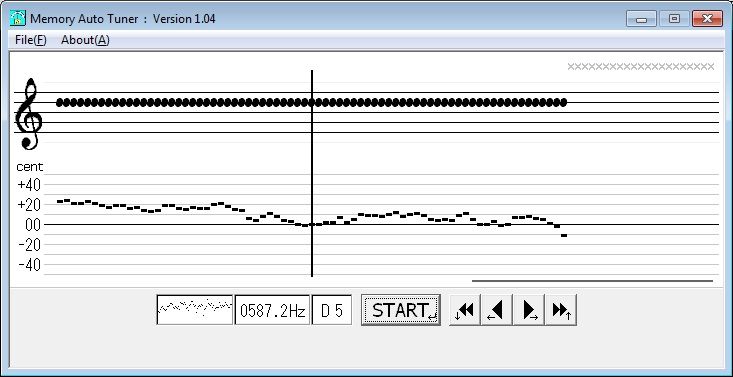

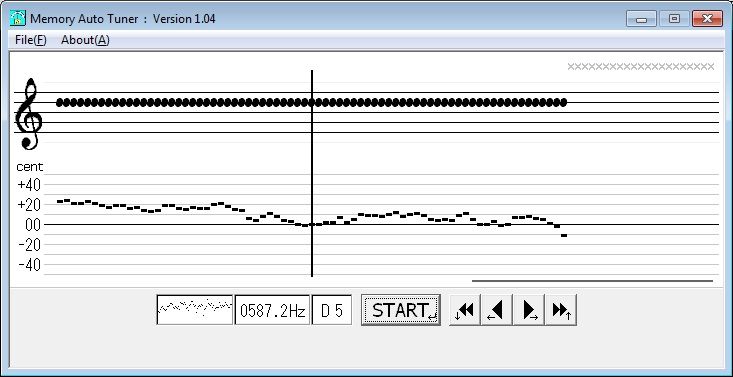

You read my earlier testimonial on your app, so you know I really like the whistle designer. But since you indicated you would make changes for usability, I wanted to pass on my thoughts on the tuner. I tried it and don't like it nearly as well as my favorite one, which is a freeware app called mTuner:

It might be obvious why just from the screen shot. It lets you stop and start and keeps up to 5000 samples. I can't find the sample length documented but my quick test says somewhere between 15 and 20 a second. You can scroll back and see the rise and fall from changes in breath control and you can use it to work on better control as well as initial tuning. It has calibration but I haven't had to use it and I am pretty certain it is dead on; I tune my daughter's guitar with it and her teacher checks it with a scope and says I tune it perfectly. These days it is hard to find a sound card that isn't really accurate since there are cheap mass produced ICs that have all the sound functions that were high end a few years ago baked into a few chips. Anyway, I don't know if I am alone in my preference for that type of display but I find it much easier to use than a scope like display.

You read my earlier testimonial on your app, so you know I really like the whistle designer. But since you indicated you would make changes for usability, I wanted to pass on my thoughts on the tuner. I tried it and don't like it nearly as well as my favorite one, which is a freeware app called mTuner:

It might be obvious why just from the screen shot. It lets you stop and start and keeps up to 5000 samples. I can't find the sample length documented but my quick test says somewhere between 15 and 20 a second. You can scroll back and see the rise and fall from changes in breath control and you can use it to work on better control as well as initial tuning. It has calibration but I haven't had to use it and I am pretty certain it is dead on; I tune my daughter's guitar with it and her teacher checks it with a scope and says I tune it perfectly. These days it is hard to find a sound card that isn't really accurate since there are cheap mass produced ICs that have all the sound functions that were high end a few years ago baked into a few chips. Anyway, I don't know if I am alone in my preference for that type of display but I find it much easier to use than a scope like display.

-Andy

- CarvedTones

- Posts: 83

- Joined: Tue Mar 23, 2010 5:39 am

- antispam: No

- Location: Raleigh, NC

- Contact:

Re: Whistle making help needed

I am having my troubles with calculations tonight. I took a wooden tube intended to be a C that I had a fipple/airway/labium in and checked the tuning. Almost a perfect B, so I decided to check the calculations. Flutomat and TWCalc were off the mark for length on a 6.2mm square window with a 14mm tube, but HB Flutomat was dead on. So I generated a plan with it and forged ahead. Cutting to length was pretty accurate; a little extra sanding, but really close. The wall thickness is 3.3mm (this is wood, intended for use in ren fairs and cosplay - a rough life - so it is thick). I am still tuning it and have already gone a couple of drill sizes larger on the first 3 holes and they are all still flat (but closing on being in tune).

-Andy

-

wormil

- Posts: 15

- Joined: Mon Jul 23, 2012 12:19 am

- antispam: No

- Please enter the next number in sequence: 10

Re: Whistle making help needed

I've built 4 whistles, only one turned out well enough to play (my inexperience, no fault of the calculators, one (4th) was an experiment in tiny whistles), but HBflutomat has been spot on for length. On the good one (my 3rd), the hole size/spacing was very close. At first the holes were a little undersized but after a day in the house, I had to drill them out to full size because the whistle had gone flat. So you might want to give it a day before going for final size. Now if I can get the head end in better shape I'll have some good whistles.

- CarvedTones

- Posts: 83

- Joined: Tue Mar 23, 2010 5:39 am

- antispam: No

- Location: Raleigh, NC

- Contact:

Re: Whistle making help needed

Length seemed to be accurate. It's funny how we are so concerned about the length, holes and spacing being perfect when we (I still struggle with it, and it seems like most novice builders do for a while) aren't consistent with the fipples. I am doing one piece historically inspired whistles in wood, so any mistakes at the head are fatal unless I do that first. Doing it first gives me some wiggle room to increase the window size slightly to get a better ramp or edge and worst case I can change the key. If I botch it completely, I toss it in a drawer for future use in multi-part instruments. The middle section of a Denner inspired late 17th century clarinet is roughly the same as a too short whistle body. I turn/bore longer tubes than I need so I get a couple of chances to make a good head. My blanks for Cs and Ds generally sound a B if I get the first fipple/edge right.wormil wrote:I've built 4 whistles, only one turned out well enough to play (my inexperience, no fault of the calculators, one (4th) was an experiment in tiny whistles), but HBflutomat has been spot on for length. On the good one (my 3rd), the hole size/spacing was very close. At first the holes were a little undersized but after a day in the house, I had to drill them out to full size because the whistle had gone flat. So you might want to give it a day before going for final size. Now if I can get the head end in better shape I'll have some good whistles.

-Andy