AR wrote:It is a high D.

The free program I used included a lot of things I didn't understand, however it seemed to suggest that a good tone comes from the harmonics produced above the basic frequency of a note, and that bigger holes allowed more harmonics. Even if they are larger than conventional designs, would it still be playable with the tips of the fingers?

Thanks

My experience leads me to believe that larger holes will produce more volume. (to a point) The harmonic overtone of each note on the whistle should be considered as a ratio of the fundamental pitch of each note (as it relates to the fundamental pitch of the whistle itself). Basically, big whistles get big holes, little whistles get little holes. I think you'll be affecting the pitch more than the tone of each note by adjusting the hole size. Haveing a really big C# hole means it will want to play flat so you will have to position the hole closer to the blade for it to be in tune. This could result in a strange finger stretch for a standard High D whistle.

Give it a shot. Good judgment comes from knowledge, knowledge comes from experience, experience comes from failure, failure comes from bad judgment.

Not that you are showing bad judgment, but hey, what have you got to lose?

Take some careful measurements of some whistles you know play well, there is nothing wrong with going with a proven technique.

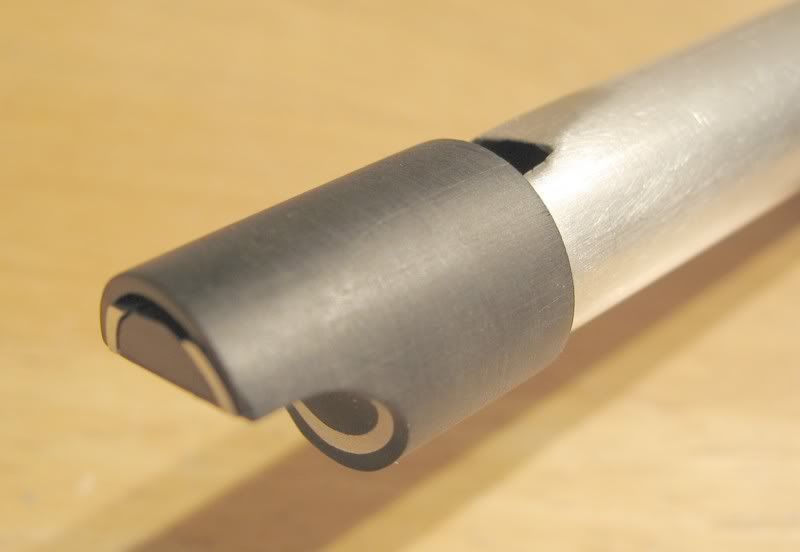

Stacey has the most bodacious fipples! & Message board

Stacey has the most bodacious fipples! & Message board